MANCHESTER TOWN HALL – STATE ROOM WINDOWS

The State Room windows had been in a poor state of repair for many years. In 2011 a scheme was proposed that would deal with health and safety issues raised by their condition.

We put together a proposal that would accommodate all the problems. We would have to work on mobile elevated working platforms, from a public square, on a Grade l building whilst working around events in the state rooms themselves and on Albert Square.

The scheme focused on all defects below head height in the rooms, this fell into opening metal sash repairs and leaded light repairs.

The metal sashes had decayed and ceased to function, most of their furniture was missing and once open, their fully open position contravened regulations for opening windows. There were also many previous poor replacement sashes, not suited to the building.

Once we began to remove the sashes from the metal frames, we soon realised that we would face further difficulties. Each face of iron was not welded nor forged to the next, as would be expected, but soldered.

This formed a weak bond between the two and explained why every opener was disintegrating. This was also the case with the fixed frames. From here, the scheme was extended to repair the large metal frames in situ.

The existing sashes were repaired and welded to improve their strength, whilst new sashes were produced to replace the previous poor repairs.

Sand Cast brass window furniture was produced from casts taken from the remaining original furniture. These included handles, back plates, catch keepers, stays and pins. Further detail was added to the handles by laithe. The metal framework was only 2.5mm in thickness, this was insufficient to tap into to fix the sashes back to the frames. Tapered fish plates were created to replicate the putty point on the rear side of the metal frames, these would give a positive fix and clamp the existing frame between the hinge and the plate.

Restrictors were designed, manufactured and fitted to the windows to limit their opening.

Once fitted, plain glazing was installed into the sashes, this was then putty pointed.

Forty two leaded lights were removed for workshop restoration. These were sectional re-builds around damaged areas. Rubbings were taken before work commenced, the lights were then “cut open” to expose the broken panes. These were replaced with matching Antique glass. Only mangled lead came was replaced, retaining as much of the original lead as possible.

In Situ leaded light repairs were also undertaken. These were done externally so that the disturbance to the lead came could not be seen from the function rooms.

Finally, the opening sashes and the fixed metal frames were painted internally and externally. The Plum colour was recreated to match the exiting colour of the frames.

Functionality and original features were restored to these unique frames.

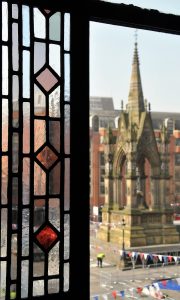

IN-SITU REPAIRS

Over the last twenty years we have undertaken many in situ repairs at Manchester Town Hall. These are often before a major event when the building is required to look at its best.

These mostly consist of repairs to leaded lights of the hallways and staircases. These damaged piece of glass is knocked out of the light, the lead rebates then cleared of any remaining glass. One side of the lead is then bent back to allow the new piece of matching glass to be inserted. The lead is then bent back and black putty is pushed between the glass and lead to form a seal and make the window watertight once more.

We have also fitted recent Lord Mayor’s names to the painted ceiling panels of the lobby outside of the Great Hall.

These were created on computer and produced in black fablon, which was then aligned and placed on the panels. We did not consider hand painting the new names on the panels as the whole panel would require kiln firing again. This firing would have the effect of deepening the colours originally used in the panel and is considered bad practice.

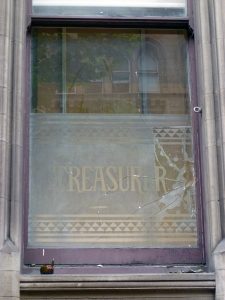

ACID ETCHED PANELS

Acid embossed or etched panels feature both internally and externally in the windows and doors of the Town Hall. Various panels have been re-created using original techniques and the acid tones of white and bright.

Rubbings and drawings are taken of the original panels before the design is then cut out of lead foil. This is then stuck to the glass to mask the areas that are not going to be affected. The relevant acid tone is then applied to the exposed areas and left “under acid” whilst it is taking affect. The longer the acid is left, the deeper it will burn into the glass.

We then produced matching profile beading to the original and glazed the panels on linseed oil putty.